Air Filters

(Pre, After & Carbon)

Product Overview

Air Filters play a critical role in maintaining compressed air quality. Air Mac Industries provides Pre Filters, After Filters, and Carbon Filters, each designed to target specific contaminants and enhance the efficiency and life of compressed air equipment.

Types of Air Filters

Pre Filter

Removes solid particles such as dust, rust, and dirt from compressed air.

After Filter

Eliminates fine oil aerosols and moisture to improve air purity.

Carbon Filter

Removes oil vapors, odors, and hydrocarbon contaminants for ultra-clean air.

Efficient Filtration for Clean & High-Quality Compressed Air

Air Mac Industries offers a complete range of air filtration solutions designed to remove dust, oil, moisture, and contaminants from compressed air systems. Our air filters help improve air quality, protect equipment, and ensure reliable system performance.

Key Features

- High filtration efficiency

- Protects downstream equipment

- Improves compressed air quality

- Durable and reliable construction

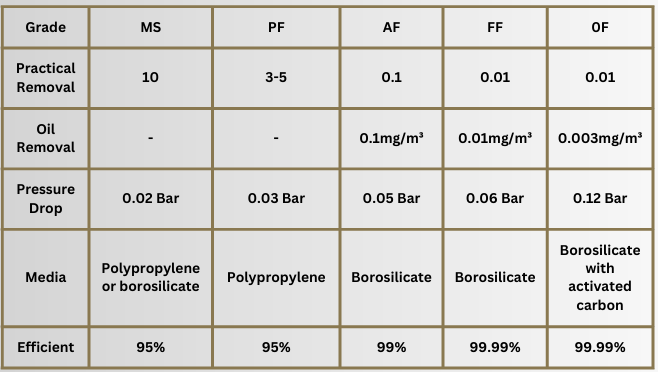

- Available in multiple filtration grades

Benefits

- Extends the life of pneumatic tools and machinery

- Ensures cleaner and safer compressed air

- Reduces maintenance and operational costs

- Supports sensitive industrial applications

Customization & Support

We assist customers in selecting the right air filter configuration based on application, air quality requirements, and system conditions to ensure optimal performance.

- Air Mac Industries air filter cartridge production includes 3 iteration stages which are designed to remove particulates, water, oil, vapor from compressed air.

- The Design of filter media ensures the effective and efficient removal of most contaminants in compressed air systems.

- All materials are suitable for operation in the temperature range up to 150° C. They are corrosion resistant and suitable for most of applications.

- The filter and cartridge size is determined by the compressed air flow. They all are designed for operating pressure up to 16 bar & 45 bar.

Technical Parameter

- Pre Filter Particle Removal - 5 Micron

- After Filter Particle Removal - 0.1 Micron

- Fine Filter Particle Removal - 0.01 Micron

- Maximum Pressure - 12 bar

- Hydro Test Pressure - 20 bar

- MOC Housing - Aluminium Pressure Die Cast

- MOC Element - Glass Fiber Media with SS Core and SS Support.